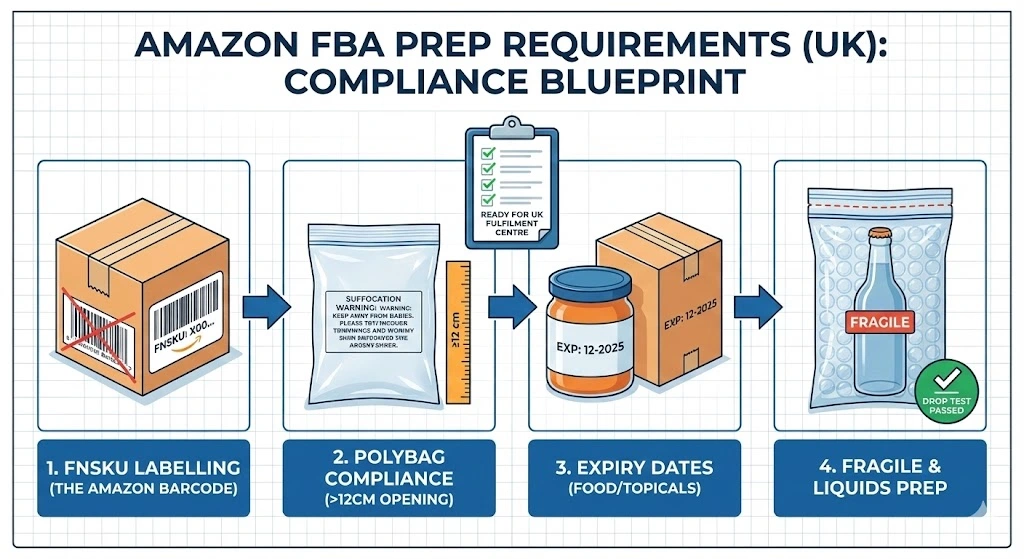

Amazon FBA Prep Requirements (UK): Packaging, Labelling, Expiry Dates, and Compliance Checklist

A definitive guide for serious sellers on how to avoid stranded inventory and rejected shipments at UK Fulfilment Centres.

Amazon’s UK fulfilment centres operate with strict compliance standards for inbound inventory. Sending inventory that doesn't meet their strict prep standards isn't just a minor error; it's a business risk that leads to shipments being delayed, flagged, sidelined, or made unavailable (stranded).

Beyond unit prep, carton-level accuracy matters: weights, dimensions, and box count need to match the shipping plan as closely as possible (and within Amazon/carrier tolerances). Mismatches at the carton level are a frequent trigger for receiving delays or investigations.

1. The Universal Requirements (Non-Negotiable)

In most cases, these are the most common requirements that cause receiving blocks at UK FBA centres.

A. The FNSKU Label (The "Amazon Barcode")

While Amazon sometimes allows commingling via manufacturer barcodes (EAN/UPC), serious sellers avoid this to prevent mixing their stock with potential counterfeits from other sellers.

Starting on March 31, 2026, barcode requirements are changing. Brand owners can continue to use manufacturer barcodes without stickers. Resellers will now be required to use Amazon barcodes for products even if they have a manufacturer barcode. [Source]

- Requirement: Apply an Amazon barcode label (FNSKU) to each unit. The format varies (often starts with X00), but the critical part is ensuring the correct FNSKU is applied to the correct SKU.

- Critical detail: This label must completely cover any existing manufacturer barcodes. If multiple barcodes are visible, it can lead to scan errors, receiving delays, rework requests, or (in clear cases) refusal.

B. Polybag Suffocation Warnings

Amazon enforces strict safety standards for plastic bags.

- Requirement: If a polybag opening exceeds 12 cm (approximately 5 inches) when measured flat, Amazon requires a suffocation warning. The warning can be printed on the bag or applied as a label.

- Critical detail: The warning must be legible and in the local language of the marketplace (English for the UK).

2. Category-Specific Rules

Depending on your product type, additional layers of prep are mandatory.

A. Expiry-Dated Products (Food, Topicals, Supplements)

Amazon UK is incredibly strict here to prevent expired goods from reaching customers.

- Format: Amazon requires the expiry date to be clear, legible, and in a format accepted for your category in the UK. In practice, MM-YYYY and DD-MM-YYYY are frequently used. Lot codes do not replace a readable expiry date.

- Visibility standard: For boxed products, Amazon requires the expiry date to appear on both the individual units and the outer (primary) box, typically in a font size large enough to be easily readable during receiving.

- Placement: The expiry date must be visible on the outside of the final sellable unit (even if inside a multipack).

- Disposal Risk: FBA may refuse reception, mark units as unfulfillable, or force removal/disposal depending on how close units are to expiration and the policy applied at that time.

B. Liquids, Creams & Gels

If it can leak, Amazon assumes it will leak. The goal is to protect other sellers' inventory in the warehouse.

- Requirement: Liquids must be prepared to prevent leaks. Depending on the product/packaging, this may include an additional sealed polybag or over-boxing.

- Test: Packaging must pass a 3-foot drop test onto a hard surface (drops on base, top, longest side, shortest side, and one corner), with no leaks/spills.

C. Fragile Items (Glass, Ceramics)

Anything breakable must be prepped to survive the rigorous FBA environment, including conveyor belts and chutes.

- Requirement: Items must be wrapped in bubble wrap or boxed individually so they pass a 3-foot drop test onto a hard surface without breaking.

- Labelling: The FNSKU label must be on the outside of the bubble wrap or protective box.

Quick Reference: Risk vs. Solution

| Requirement | The Risk | Fast Prep Solution |

|---|---|---|

| FNSKU Coverage | Scan errors / Stranded inventory | Gatekeeper check & relabeling |

| Polybag Warning | Receiving hold / non-compliance issue | Compliant bags used as standard |

| Expiry Visibility | Receiving delays / Disposal | Expiry audit & external labeling |

3. The UK FBA Compliance Checklist

Before finalizing any shipment plan, run your inventory through this final check.

Pre-Shipment Final Check:

- Are all manufacturer barcodes completely covered by FNSKU labels?

- Do all polybags (opening ≥ 5" / 12.7 cm when measured flat) have correct suffocation warnings?

- Are expiry dates human-readable, visible, and in an accepted format?

- Are liquids sealed to pass the 3-foot drop test?

- If a carton exceeds common manual-handling thresholds (e.g., 15kg / 23kg), have you applied the correct heavy labels per Amazon/carrier guidance?

- Is the shipping label placed flat on the carton side, avoiding seams and tape?

Official Amazon references (UK Seller Central): Product Packaging & Prep Requirements, Use manufacturer barcodes, Barcode Requirements Changes (2026), Expiry Date Requirements. Amazon policies are subject to change and may vary by category.

4. How Fast Prep UK Guarantees Compliance

Meeting these requirements manually is time-consuming and prone to human error. At Fast Prep Center UK, compliance isn't a "best effort"—it's embedded into our workflow.

- Systemised Knowledge: We follow category-specific prep rules and run a final compliance check before dispatch.

- Standardised Materials: We exclusively use compliant polybags with warnings and industrial-grade bubble wrap.

- The "Gatekeeper" Check: Our final inspection before boxing ensures that every unit leaving our facility is scannable and compliant.

We handle the complex rulebook so you can focus on sourcing products.

Ensure your next shipment is compliant.

Stop worrying about rejected shipments. Let professionals handle the prep requirements.